Costing Methods & Profitability

Accurate inventory costing sits at the center of every healthy business. Whether you manufacture, distribute, design apparel, manage complex supply chains, or run retail operations, the valuation of your inventory directly influences margins, financial reporting, replenishment decisions, analytics, and long-term profitability.

Yet many organizations unintentionally undermine these outcomes by selecting the wrong costing method, relying on outdated rules, or failing to maintain costing discipline. At CKS, we routinely help companies discover hidden costing errors, margin distortions, and reconciliation problems—and replace them with a streamlined costing strategy built for growth.

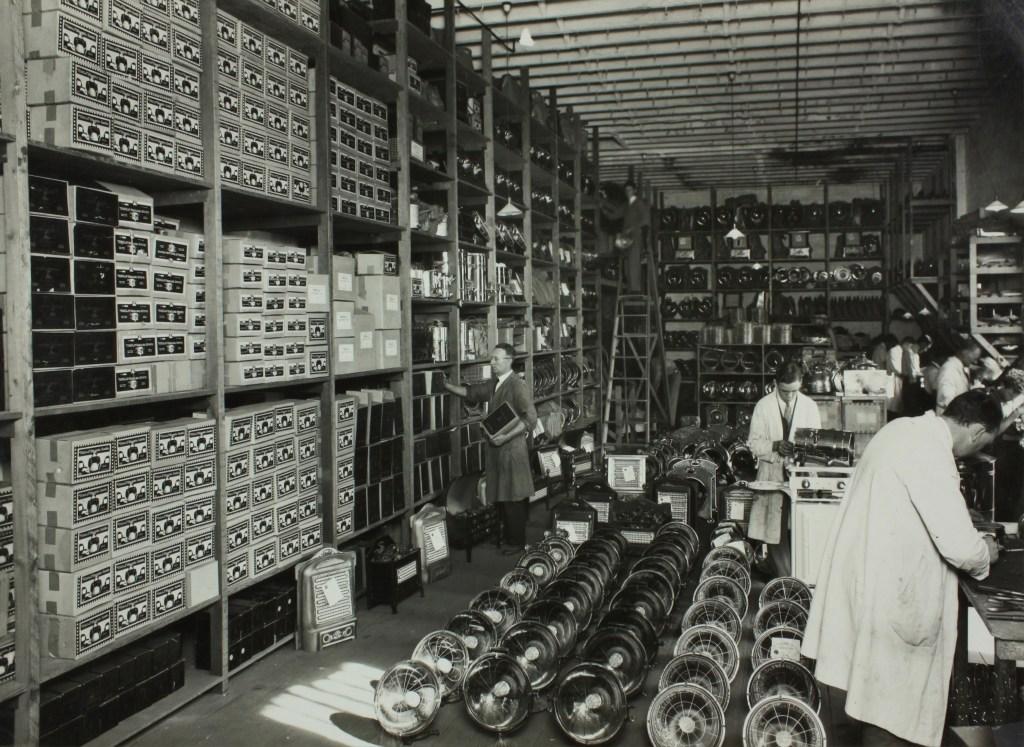

Featured Photo (left) by Russ Murray / @remages

CKS Inventory Costing Methods: Overview

Best used when product cost is stable or items have a limited shelf life.

Pros:

- Intuitive flow.

- Higher inventory valuation in rising markets.

- Improves creditworthiness.

Cons:

- Higher taxable income.

- Can distort margins during cost volatility.

Best for environments where inventory levels consistently increase over time.

Pros:

- Lower taxable income during inflation.

- Reflects current replacement cost.

Cons:

- Lower inventory valuation.

- Disallowed in many countries.

- Can distort management visibility.

Best for unique, serial-numbered, high-value, or regulated items.

Pros:

- Highest accuracy.

- Ideal for luxury goods, serialized equipment.

- Clear auditability.

Cons:

- Operationally intensive.

- Not scalable for high-volume SKUs.

Best for unstable pricing or co-mingled inventory.

Pros:

- Smooths price volatility.

- Easy to maintain.

- Simplifies accounting

Cons:

- Less precision.

- Can distort margins after large purchases.

Best in repetitive manufacturing and cost-controlled environments.

Pros:

- Strong cost control discipline.

- Predictable planning and pricing.

- Useful for performance benchmarking.

Cons:

- Requires continuous maintenance.

- Misleading if standards are outdated.

- Requires variance reconciliation.

>> Inventory Accuracy & Valuation Control

We eliminate unreconciled cost layers, misapplied methods, incorrect adjustments, and margin inconsistencies.

>> Production & Supply Chain Optimization

We provide clarity into true production costs, lead-time effects, make-vs-buy analysis, and profitability per SKU or style.

>> Analytics That Reveal Real Profitability

We improve visibility into contribution margin, landed cost, style-level profitability, and forecasting accuracy.

>> Higher Profit Margins Through Costing Discipline

Clients see reduced margin leakage, better purchasing, improved pricing decisions, and stronger inventory turnover.

Selecting the right inventory costing method is not just an accounting choice—it’s a strategic decision.

CKS helps organizations build and maintain costing strategies that drive profitability, accuracy, and long-term growth.

Leave a comment